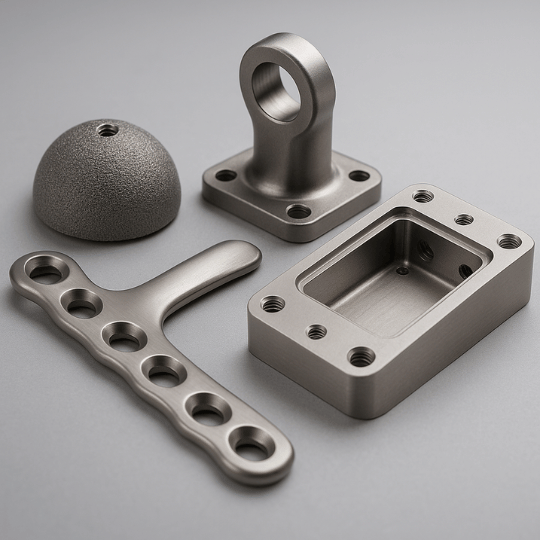

Medical Implants

At PMP Precision Engineering, we understand the critical importance of precision, reliability, and biocompatibility in the manufacturing of medical implant components. These components lie at the heart of life-saving and life-enhancing technologies and must meet the most stringent regulatory requirements, including CE marking and other globally recognized medical certifications.

Our expertise lies in the precision machining of biocompatible materials, carefully selected to meet both clinical performance and safety standards:

Titanium

Lightweight, corrosion-resistant, and ideal for long-term implantation — particularly in orthopedic and dental applications.

Stainless Steel

Durable, sterilizable, and widely used in orthopedic implants, surgical instruments, and trauma fixation devices.

Medical-Grade Polymers

Flexible, resilient, and biocompatible — ideal for non-metallic implants and structural support components.

These materials are specifically chosen to minimize biological risks such as infection, inflammation, and rejection, while maintaining mechanical integrity and long-term clinical performance.

With deep expertise in advanced CNC machining, tight-tolerance engineering, and rigorous quality control, we manufacture implant components built to perform under the body’s most demanding physiological conditions. Each part is engineered for structural reliability, precision fit, and lasting function — even in extended clinical use.

Trust PMP Precision Engineering to deliver medical implant components that meet the highest benchmarks of safety, durability, and clinical excellence — because when lives are on the line, precision matters most.

Why Work With Us?

Features and Benefits

Why Choose PMP Precision Engineering for Mold Solutions?

🛠️ Durability

Robust, long-lasting molds engineered to withstand multiple production cycles — maintaining consistent performance with minimal wear and maintenance.

💰 Cost-Effective Solutions

Smart, efficient designs that reduce tooling costs, optimize material usage, and lower overall production expenses — without compromising precision.

⏱️ Quick Turnaround Time

With streamlined workflows and in-house tooling expertise, we ensure on-time delivery of molds that meet the most demanding production schedules.

Choose PMP Precision Engineering for mold solutions that are reliable, cost-efficient, and precisely tailored to your unique production needs — from prototyping to full-scale manufacturing.