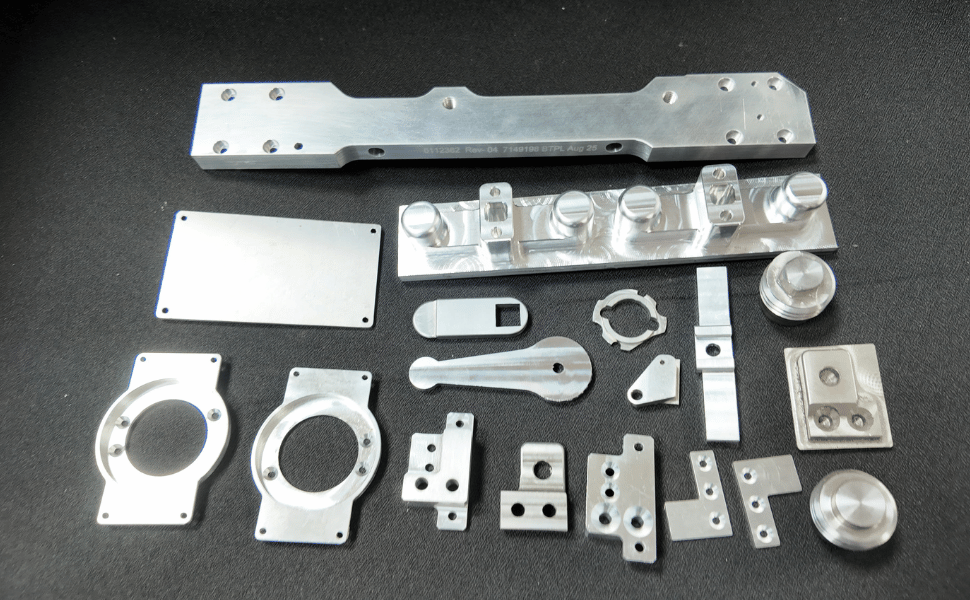

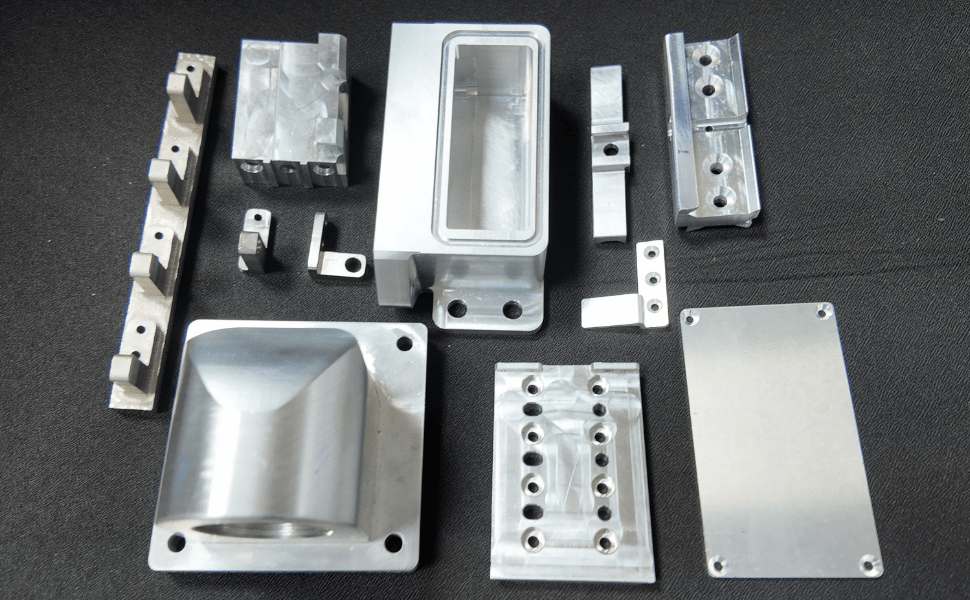

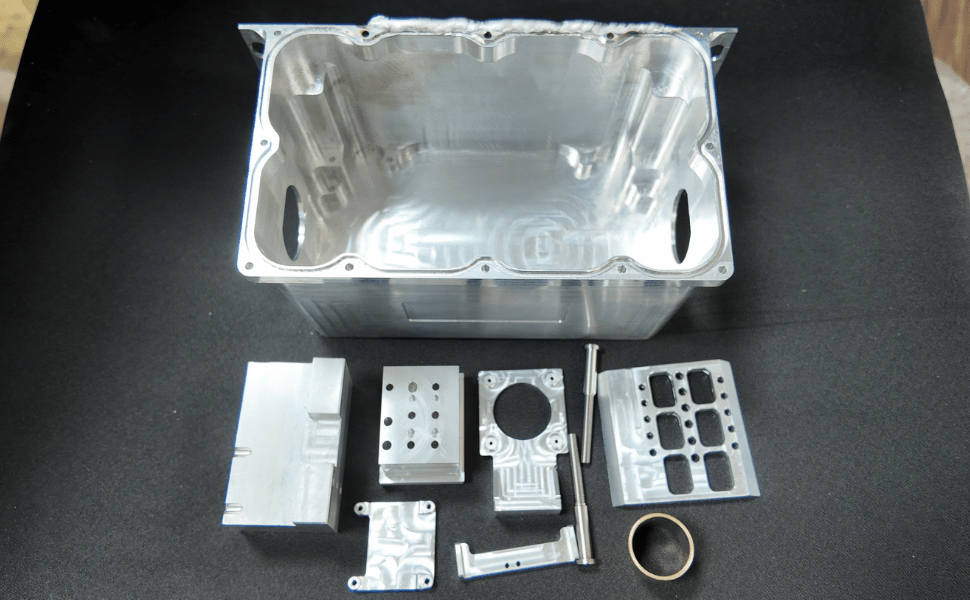

Precision Beyond Manufacturing

At PMP Precision Engineering, we go beyond manufacturing high-precision components — we ensure they reach you on time, in full, and exactly as specified. Our comprehensive End-to-End Supply Chain Services are designed to manage the complete product journey — from raw material procurement to final delivery — with full visibility and control at every stage.

By integrating sourcing, inventory management, production scheduling, logistics, and customer coordination into a unified workflow, we eliminate inefficiencies and minimize the risk of disruptions. This proactive approach enables us to shorten lead times, reduce errors, and optimize costs — ensuring you receive the right product, at the right time, without compromise.

At PMP Precision Engineering, supply chain excellence isn’t just a backend operation — it’s a core part of our precision promise.

What We Offer

At PMP Precision Engineering, our supply chain management is built for precision, efficiency, and reliability — ensuring that every component arrives exactly as required, every time. We manage the entire lifecycle with meticulous attention to detail:

Procurement

We source high-grade raw materials and components from certified, trusted suppliers — ensuring uncompromised quality from the very start.

Inventory Management

Our tightly controlled inventory systems support lean manufacturing and just-in-time (JIT) fulfillment, minimizing waste and improving turnaround times.

Production Scheduling

With intelligent planning tools and expert coordination, we optimize quality, speed, and flexibility to meet even the most demanding project timelines.

Packaging & Kitting

We offer custom packing, labeling, and kitting solutions tailored to your operational needs — ensuring safe handling, easy identification, and smooth downstream integration.

Logistics & Delivery

From local dispatches to global freight, our logistics team guarantees secure, on-time delivery, aligned perfectly with your schedules and documentation requirements.

Why Choose Our Supply Chain Services?

What Sets Our Supply Chain Apart

At PMP Precision Engineering, our supply chain isn’t just efficient — it’s engineered for precision, accountability, and responsiveness. Here’s how we ensure your parts arrive exactly when and how you need them:

🚚 Reliable Fulfillment

Consistent, accurate, and on-time deliveries you can count on — every shipment, every time.

🔁 Integrated Process Flow

Seamless coordination between design, production, quality, and logistics ensures nothing falls through the cracks.

💡 Real-Time Tracking

Gain complete visibility into materials, inventory status, and order progress, keeping you informed and in control at every stage.

📦 Custom Logistics

Tailored shipping, packing, and scheduling solutions designed to align perfectly with your production pace and operational priorities.

🏷️ Documentation & Compliance

Every delivery is backed by inspection reports, certifications, and full traceability, ensuring smooth audits and regulatory compliance without delays.

Let’s Simplify the Complex

Supply Chain as a Strategic Advantage

With PMP Precision Engineering, your supply chain becomes a strategic advantage. We manage complexity, streamline operations, and ensure every component reaches you with precision and reliability — so you can focus on what matters most: innovation, growth, and delivering excellence to your customers.

Industries We Support

✈️ Aerospace

Full traceability, rigorous documentation, and compliance with aerospace-grade quality standards at every stage of the supply chain.

🛡️ Defense

Secured logistics, controlled inventory environments, and mission-critical delivery coordination designed for high-stakes, defense-grade programs.

🏥 Medical

Sterile, damage-free packaging and tightly managed delivery timelines to meet healthcare-level precision and reliability requirements.

🚗 Automotive

Agile fulfillment aligned with your production schedules, testing milestones, and component validation checkpoints — ensuring zero delays and consistent performance.