Scalable. Streamlined. Reliable.

At PMP Precision Engineering, we specialize in precision-driven production tailored to meet the rigorous demands of the aerospace, defense, medical, and automotive industries. Whether you’re launching a small-batch prototype or scaling up to full-volume manufacturing, our production systems are engineered to deliver high-quality components with unmatched speed, consistency, and repeatability.

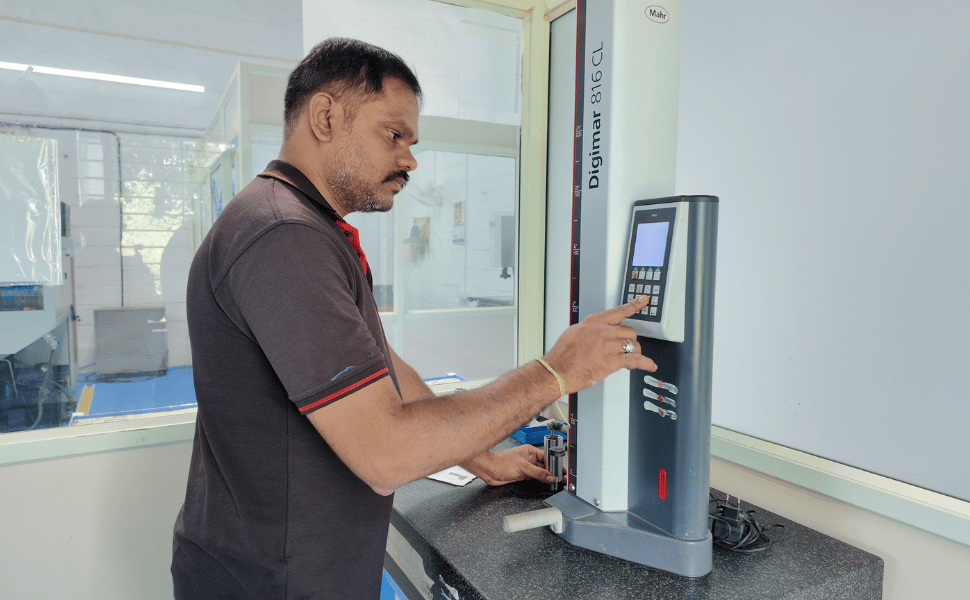

Our state-of-the-art facility is equipped with advanced CNC and VMC machining centers, precision tooling, and integrated inspection systems. This robust infrastructure enables us to achieve tight tolerances, complex geometries, and critical performance specifications across a wide variety of materials — including aluminum, stainless steel, titanium, and engineering plastics.

With a strong emphasis on process control, lean manufacturing, and quality assurance, we ensure that every component leaving our facility is built to perform exactly as designed — every time.

Our Capabilities

Production Capabilities

At PMP Precision Engineering, our production services are built for precision, flexibility, and scalability — ensuring every component meets your technical, quality, and delivery requirements with consistency and reliability.

CNC & VMC Machining

Multi-axis, high-speed machining designed for complex geometries, tight tolerances, and repeatable accuracy across a broad range of materials.

Batch & Volume Production

Scalable manufacturing solutions — from one-off prototypes to full-scale production runs, maintaining consistent quality at every quantity.

Material Versatility

Expertise in machining aluminum, stainless steel, titanium, engineering plastics, and specialty alloys, serving the diverse requirements of industries such as aerospace, defense, and medical.

Assembly Support

Integration of mechanical sub-assemblies, kitting, and component grouping to streamline downstream operations, reduce lead times, and enhance production efficiency.

Real-Time Monitoring

Digitally managed, process-controlled workflows with real-time traceability — ensuring quality assurance, regulatory compliance, and complete production visibility from start to finish.

Production Workflow

At PMP Precision Engineering, every project follows a structured, quality-first workflow to ensure precision, consistency, and on-time delivery — no matter the scale or complexity.

Planning & Tooling Setup

Meticulous planning and custom tooling preparation, aligned precisely with your specifications, set the foundation for a streamlined and efficient production process.

In-Process Quality Checks

Real-time inspections and dimensional validations during machining help detect deviations early, maintaining critical tolerances and ensuring part integrity.

Final Inspection & Documentation

Comprehensive quality checks, surface finish assessments, and full documentation guarantee compliance with industry standards and customer audit requirements.

Packaging & Dispatch

Secure, clearly labeled packaging and coordinated logistics ensure your components are delivered safely, accurately, and on schedule.

Each stage is managed with an unwavering commitment to efficiency, quality, and your unique project requirements — because at PMP Precision Engineering, delivering excellence isn’t just our goal, it’s our standard.

Why Choose Our Production Services?

Why Our Production Stands Out

At PMP Precision Engineering, we combine advanced technology, skilled expertise, and disciplined execution to deliver components that perform — every single time.

🛠️ High Repeatability

Our precision-driven processes ensure every part meets exact specifications — consistently, batch after batch.

🚚 Timely Delivery

We align production schedules with your project timelines, meeting tight deadlines without ever compromising on quality.

💡 Smart Manufacturing

Through digitally enabled systems, real-time monitoring, and data-driven feedback loops, we drive efficiency and continuous improvement across every stage of production.

📦 Custom Fulfillment

From tailored packaging and labeling to detailed shipping and documentation, we deliver exactly what your operations demand — accurately, securely, and on time.